Commercial blast chillers

In the wide range of professional food service equipment, commercial blast chillers play a crucial role. These devices are designed to rapidly lower the temperature of food and preserve its organoleptic characteristics during storage. The blast chillers available on Bakeit are Made in Italy products that represent excellence in the field and are the ideal choice for those seeking professional solutions for cooling and freezing.

How does a professional blast chiller work?

Blast chillers operate through a process of rapid cooling or freezing, preventing bacterial proliferation and the loss of food quality. Essentially, these devices reduce the temperature of food from high levels to safe storage temperatures in a short span of time.

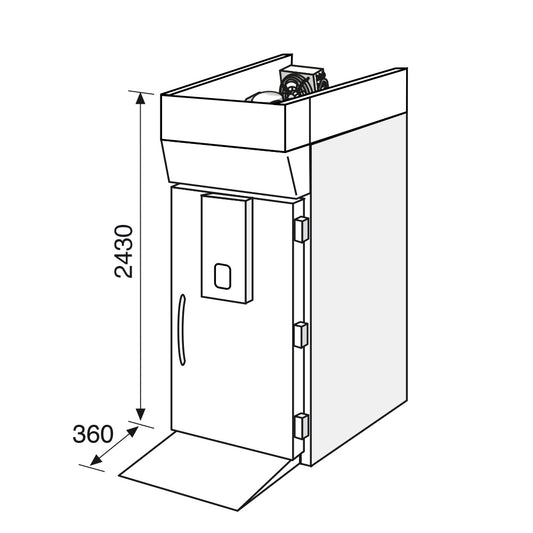

Among the most popular models is the professional blast freezer. This device can hold up to 20 trays and is constructed entirely of Aisi 304 stainless steel, both internally and externally. Its key features include the ability to rapidly cool from +90°C to +3°C and freeze from +90°C to -18°C. It also has a digital electronic control panel for precise management of the chilling and freezing process.

If you need a solution with greater capacity, the trolley blast freezer might be the best choice for you. This device can accommodate GN1/1, GN2/1, EN60x40, and EN60x80 trolleys and features a digital command panel with a color graphic display and touch-sensitive keys. Thanks to its large capacity and advanced technology, it is perfect for large food laboratories.

What temperature can a blast chiller reach?

The temperature a blast chiller can lower food at, depends on the specific model. Generally, blast chillers are capable of reducing the temperature of food from +90°C to +3°C or lower, ensuring rapid cooling or freezing.

Why choose a blast chiller?

Choosing a blast chiller is essential to ensure food safety and the quality of your products. Our range of blast chillers offers solutions suitable for various kitchen sizes and needs. By choosing one of our models, you can rely on reliable performance and excellent results.

The blast chillers on Bakeit are made with care and attention in Italy, following strict quality standards. By choosing a Made in Italy blast chiller, you invest in high-level performance and the artisan tradition that characterizes our country in the food industry.

Contact us today for more information on blast chillers to find the best solution for your specific needs.

Frequently asked questions about professional blast chillers

Discover everything there is to know about the world of commercial blast chillers:

-

How much does a blast chiller cost?

The cost of a professional blast chiller varies based on size, the range of features, and the brand. On Bakeit.it, you find professional models suitable for every need, with competitive prices and the possibility of consulting to choose the best option for your business.

-

How to choose a commercial blast chiller?

Choosing an industrial blast chiller depends on various factors: the necessary capacity based on the volume of production, the type of product, and the available space in the laboratory. We recommend personalized consultation to identify the most suitable model.

-

What types of professional blast freezers can you find on Bakeit?

On Bakeit, you find a wide range of professional blast freezers, from compact models for small productions to large-capacity industrial models. Available in various sizes and configurations, to meet every need of restaurants, pastry shops, ice cream parlors, bakeries, and food laboratories. Each model is designed to ensure maximum efficiency, food safety, and compliance with current regulations.

-

Automatic programming of the thermal blast chiller

The latest generation blast chillers offer automatic programming functionality, allowing easy selection of the most suitable chilling or freezing cycle depending on the type of food. This feature ensures optimal results with minimal effort, improving the efficiency of your kitchen.

-

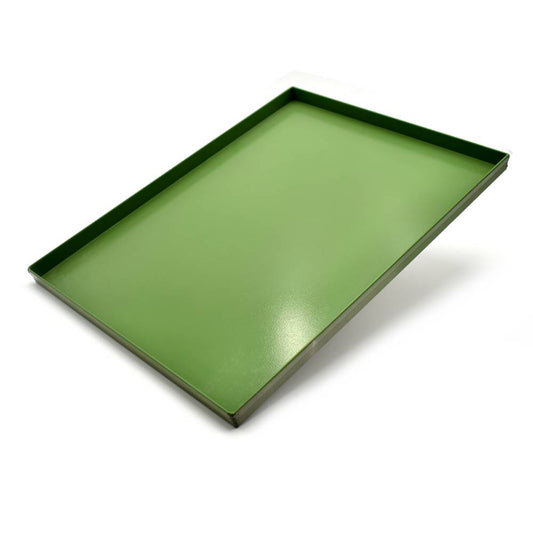

Are trays included in the blast chillers?

Trays are not directly available inside the blast chiller. However, in our BakeIt store, we offer a wide selection of trays specifically designed for use with the blast chiller. These trays are ideal for freezing and working in cold environments, ensuring maximum compatibility and safety during the cooling or freezing process of foods.

-

How to use a professional blast chiller?

To use a blast chiller, select the desired program based on the type of food and the required function (rapid cooling or freezing of the product). Place the foods inside, ensuring they are correctly distributed, and start the cycle. There are two cycle modes to choose from: time cycle, setting the desired duration for the chilling process, and alternatively, the thermal probe cycle.

-

What precautions should be taken before installing a blast chiller in the kitchen?

Before installing a blast chiller, it is essential to ensure that the kitchen has adequate workspace, correct electrical supply, and sufficient ventilation for the proper operation of the equipment. Furthermore, it is always recommended to assess accessibility for proper maintenance and cleaning of the product.

-

How should foods be stored in the rapid temperature blast chiller?

Foods should be evenly arranged inside the blast chiller, avoiding overlapping to ensure proper circulation of cold air. It is advisable to use compatible trays and racks to maximize the efficiency of the product's chilling times.

-

What is the core temperature probe for? Is it included in the heat blast chillers?

The core temperature probe, integrated into the blast chiller, allows for the use of the thermal probe cycle mode. This means placing the probe inside the product, setting the desired temperature, and starting the chiller. Once the probe reaches the set temperature, the freezing or chilling process automatically stops. At this point, the chiller switches to maintenance mode, ensuring that the product remains preserved at the desired temperature after the chilling or freezing process. Yes, in Bakeit's blast chillers, the probe is always included.

-

Why is the chilling of raw fish indispensable for health?

Chilling raw fish is an essential process to eliminate health risks related to the presence of parasites. This process ensures that the fish can be safely consumed while maintaining its freshness and nutritional properties.

-

How long is it necessary to chill fish for its consumption to be considered safe?

To ensure the safe consumption of raw fish, regulations require a thermal chilling process that reaches -20°C at the core of the product for at least 24 hours. This process ensures the elimination of parasites such as Anisakis.

-

Blast chiller for ice cream: which Bakeit chillers are ideal for the ice cream shop?

For ice cream shops, Bakeit offers blast chillers specifically designed for ice cream, ensuring optimal crystallization and preservation of the product. These chillers are essential for maintaining the ideal quality and consistency of ice cream, with rapid and efficient chilling and freezing cycles.