Professional Baking Trays

Bakeit professional baking trays are designed for intensive use in bakeries, pastry shops, pizzerias, delis, and HO.RE.CA. laboratories. Engineered to withstand high temperatures, they ensure consistent and long-lasting results due to the careful selection of materials, tailored to meet different production requirements:

- Aluminum: lightweight and highly conductive, ideal for bread, brioche, and sweet baked goods.

- Aluminized Steel: perfect for pizza, focaccia, and pinsa, it retains heat longer and guarantees superior crispness.

- Stainless Steel: ideal for boiling taralli. Upon request, we can also supply stainless steel trays for industries outside the food sector (e.g., pharmaceutical or chemical industries).

Tray Sizes for Bakeries, Pastry Shops, or Pizzerias

Bakeit professional trays are available in a wide range of standard and custom sizes to perfectly suit the needs of every artisan or industrial laboratory. Available sizes:- 40x60 cm (also known as Euronorm): the most requested size in the pastry and pizzeria sectors, compatible with most professional ovens and equipment.

- 60x80 cm: ideal for bakeries and large-scale production, thanks to its larger capacity.

- Other sizes: also available in dimensions such as 50x70, 80x80, and 80x100 cm, as well as custom sizes upon request, following evaluation by our technical department.

Frequently Asked Questions about Professional Baking Trays

Do you have doubts about which tray to choose or how to use it most effectively? Here are the answers to the most common questions from our customers.How to choose the most suitable professional baking tray?

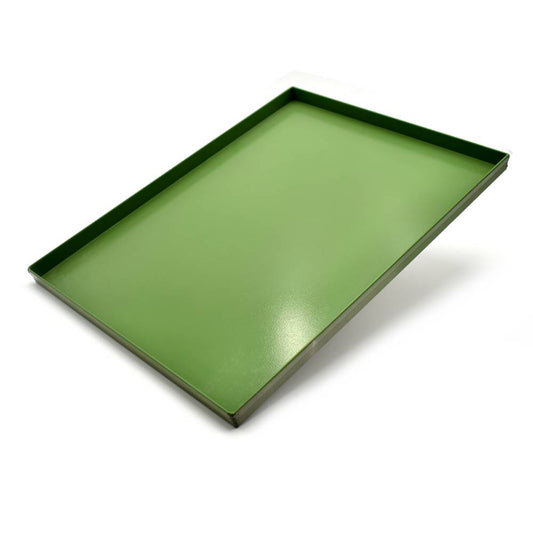

The choice depends on the type of production in your laboratory:- For bread production, perforated flat aluminum trays with a non-stick coating are ideal, lightweight, and easy to handle.

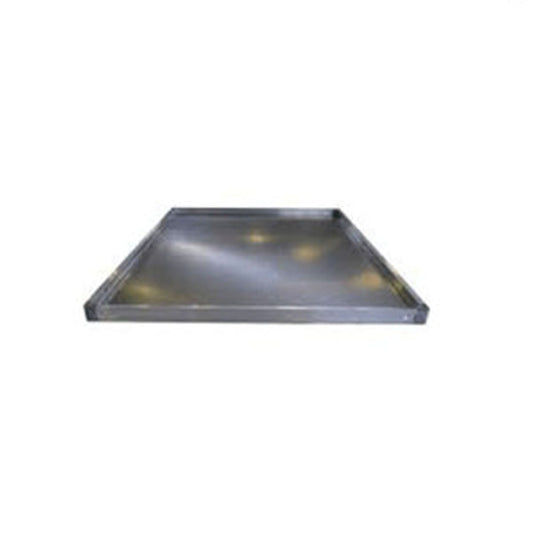

- For pastry or pizza, aluminized steel trays are preferred, offering optimal heat conduction for even baking.

What is the difference between a perforated tray and a solid tray?

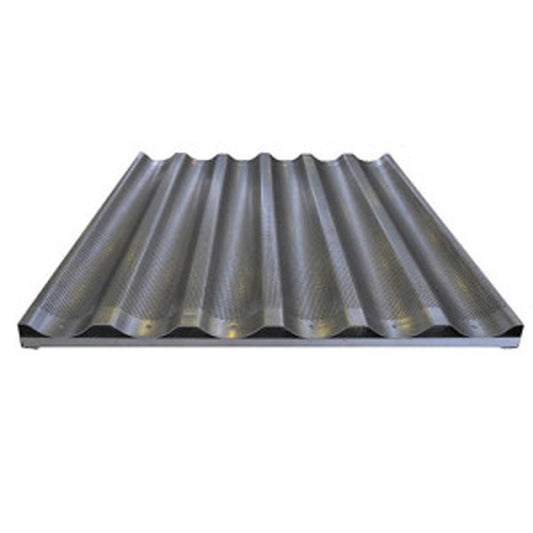

The choice depends on the type of oven you intend to use:- Perforated aluminum tray: perfect for ventilated ovens (rotary or convection), the holes allow heat to circulate better, ensuring uniform baking.

- Solid aluminum tray: for static baking typical of traditional or so-called deck ovens, the flat tray is the best choice as heat is transferred from both the base and radiation from the heating elements or steam tubes, ensuring optimal results.

Professional tray with frame or with crossbar: which one to choose?

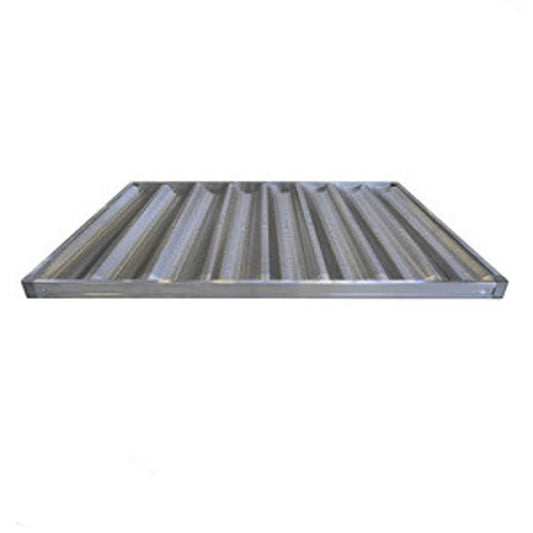

The differences mainly concern construction:- Corrugated tray with frame: more robust and stable, suitable for automatic or high-intensity operations or when it needs to be integrated into automatic machines.

- Tray with crossbar: lighter and more manageable, ideal for manual loading and unloading of bread, thanks to the open side that facilitates the process.

Both are designed to ensure efficiency and quality in professional baking.